Their knowledge is often based on decades of experience: Machine and plant operators are hard to replace – they hear and feel their machines. So, what can be done when there are no successors? One possibility is to imitate this know-how digitally. Here, Revolution Pis can support knowledge management without interfering with existing systems.

Companies face that experienced employees are taking their accumulated knowledge into their well-deserved retirement. This loss weighs particularly heavily when machine and plant operators know their machines inside out. After all, if you know a plant like the back of your hand, you operate it much more efficiently. Operating data shows that OEE (overall equipment effectiveness) drops by up to 30 percent with inexperienced personnel.

How’s the Revolution Pi helping?

With the RevPi, plants can be equipped with additional sensors to detect and measure anomalies. There is no need to intervene in existing control systems to collect data. Additionally, the Revolution Pi can also be used to simulate manual interventions on physical controls such as pushbuttons, speed controls, keystrokes or HMI and their possible settings.

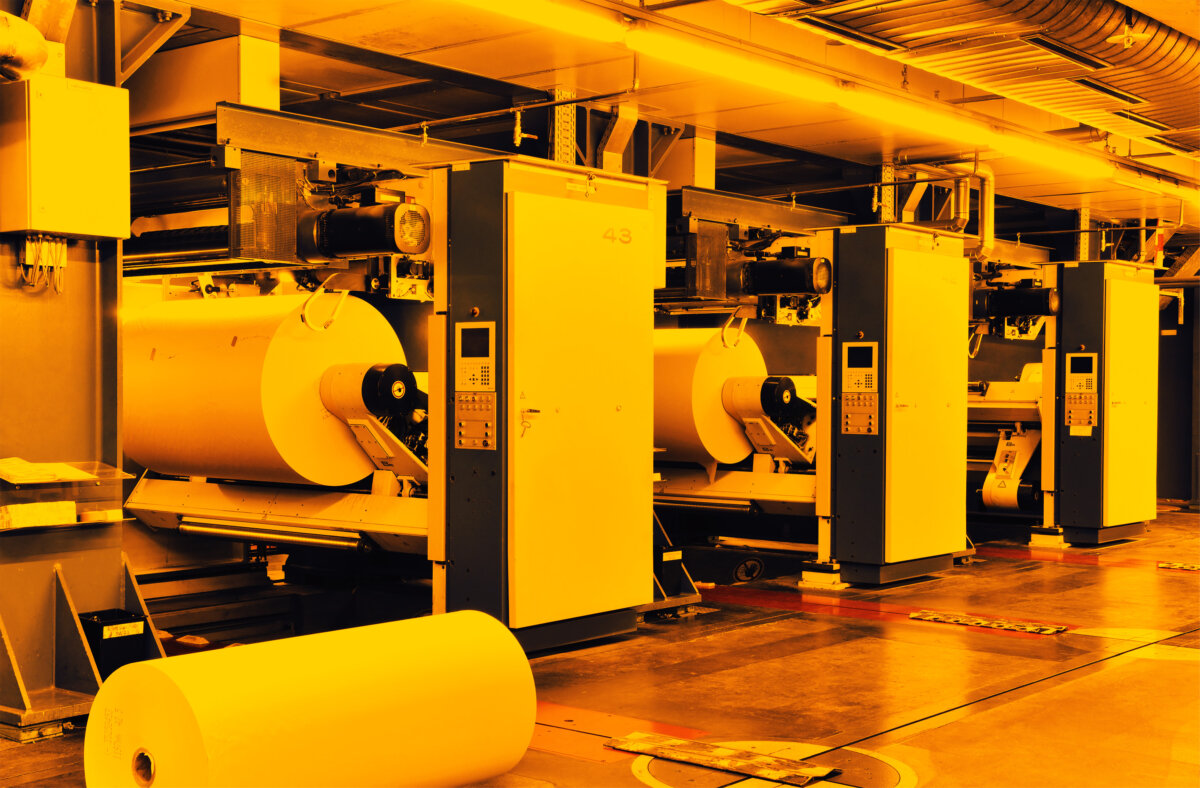

An example from the paper industry

In printing plants, paper runs over enormous numbers of rolls, rollers, and bearings. Here, fires with devastating effects can quickly occur as a result of defective parts – knowledge about the equipment and its maintenance is therefore a must. Anyone who has spent decades in production knows every detail of their plant. Even the smallest acoustic changes will make them sit up and take notice. Placing a hand in the right place can reveal unusual heating or vibrations in the machine and provide clues as to which part is causing problems. Further checks and measures are then carried out directly at the correct position. Experienced personnel therefore not only minimize unplanned downtimes due to malfunctions or safety risks, but also shorten lengthy fault isolations.

The solution with the Revolution Pi

If this experience cannot be passed on, it should be digitally imitated: Without interfering with the existing control system, additional temperature and vibro-acoustic sensors provide similar insights. The collected data is evaluated by the Revolution Pi and displayed on a dashboard. Depending on the software used, alarms are triggered via threshold or anomaly detection. The Revolution Pi can then operate optical or acoustic signals or digitally notify the problem via e-mail, push message or old-school via SMS.

Knowledge Management: Preserving experience digitally with RevPis

Preserving knowledge is important, but unfortunately not always possible when employees retire or change companies. Often, employers are under time pressure to digitize valuable experience before it is lost. With its variety of uses, the Revolution Pi is becoming an all-purpose tool in the battle to preserve decades of know-how.