HMI with Revolution Pi and Node-RED in Production Environments

A team of production staff, IT, and business development meets and shows how easy it is to install an HMI with Revolution Pi and Node-RED in our production. Our exemplary use case: the partial automation of our THT assembly.

THT Assembly

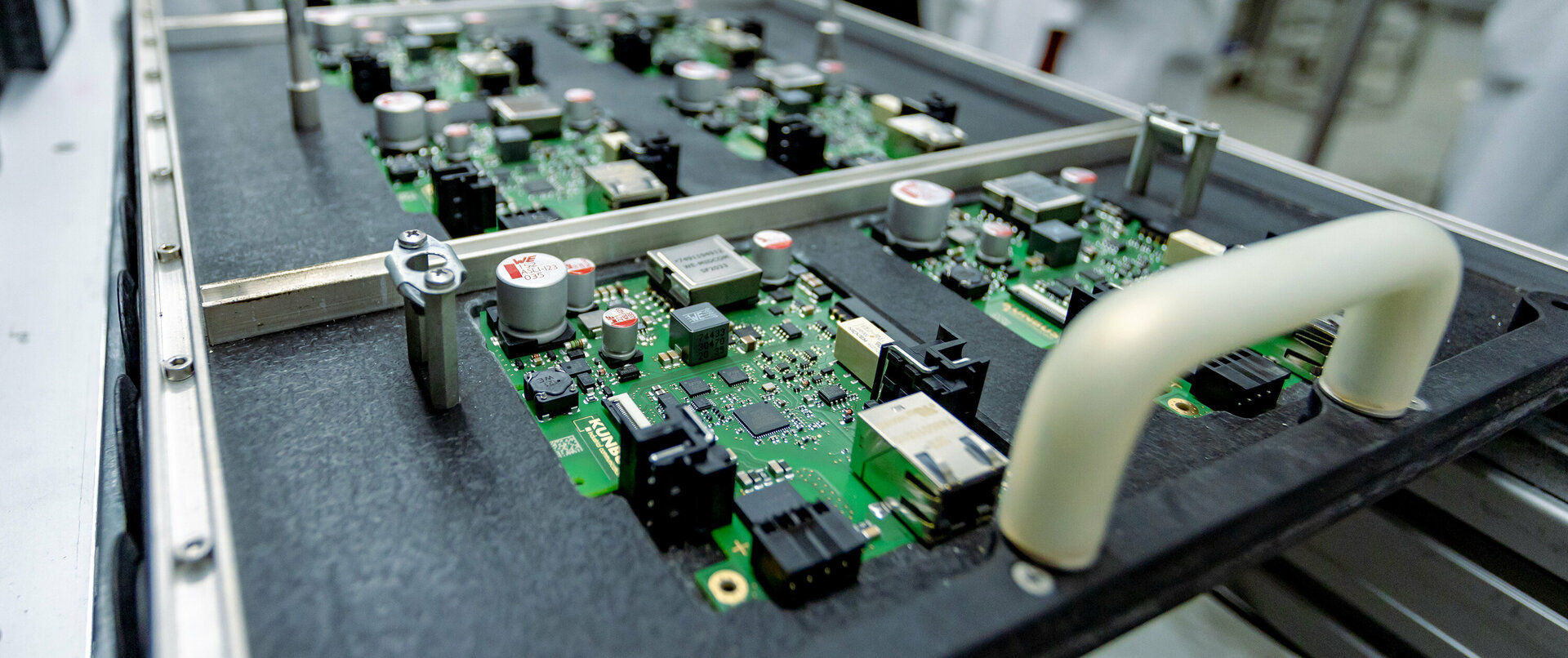

In addition to machine SMD assembly, larger parts must be attached to RevPis by hand (THT assembly). The advantage of this is that the components can be bonded to the PCB with sufficient strength. Which makes the RevPis particularly resistant to environmental stress.

Show Assembly Plans

To simplify the manual process, the display of the assembly plans was automated – with a Revolution Pi Connect. This makes it easier, especially for new employees, to get started: A quick look at the templates is required when the type of board to be assembled changes – and manually clicking through the plans after each soldering frame are unnecessary steps.

HMI and Node-RED

The appropriate assembly plans are now displayed on a touch screen. An RFID reader recognizes the device to be assembled based on the soldering frame. The correct plan is then loaded from our ERP MS SQL database, the existing PDF file is converted into a PNG file, copied to the RevPi Connect and finally loaded onto a clear web front end. The entire application was programmed with the open source application Node-RED.

Teamwork Makes the RevPi Work

The process was perfected through cross-departmental expertise: The project was led by Business Developer Boris, who, as a maker-at-heart, regularly expands his field of action to internal business development. Our production staff Doris, Tülin, Despoina, Draga, Sophie, and Frank checked and improved Boris’ initial concept. Production engineering and IT worked on the interfaces to existing systems. “It was particularly important to us that the scanners and storage locations are exactly where we are in the workflow anyway,” Draga summarizes the team’s considerations. As a long-time employee, she is a true professional – even if she modestly denies it. Her experience with almost all existing production machines has enabled her to give good advice.

“I am happy that it works so smoothly now. And it’s just fun to work on something new,” Draga adds. In addition to Boris, André (IT), Erhan and Bato (both production) were responsible for the final project completion, with whose help the hardware could be functionally assembled and put into operation.