Retrofit Hydropower Plant

Challenge

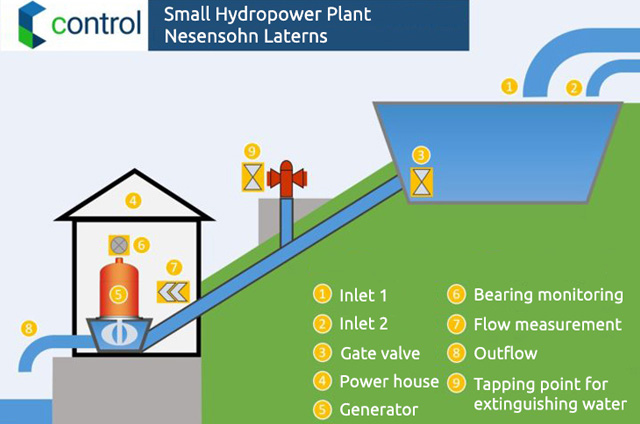

The extensive facility posed special requirements for digitalization: The high-level reservoir is located one kilometer from the main power plant. Technical installations such as level measurement, temperature recording, and pressure line monitoring needed to be integrated into centralized monitoring. Additionally, it was necessary to integrate existing components robustly and securely into a cloud-based IoT environment.

Built in 1922, the Nesensohn small hydropower plant in Austria originally supplied the local community with electricity. Today, the modernized facility feeds energy into the public grid. The technical implementation was carried out by digifai, an industrial IoT solutions specialist from Dornbirn.

Solution

digifai chose Revolution Pi as the central hardware platform. The RevPi Connect impressed with its modularity, industrial suitability, and support for numerous protocols. Complemented by the "control" IoT platform, the system enables reliable collection and transmission of sensor data to the cloud.

The solution's open architecture also facilitates the integration of existing components and allows for future expansions. Thanks to machine learning, the system continuously optimizes processes, detects deviations early, and improves operational efficiency.

Implementation

digifai's project team implemented a comprehensive monitoring system that networks all plant components. The RevPi Connect serves as an IIoT gateway, collecting, processing, and transferring sensor data to the IoT platform. Additionally, real-time monitoring with remote access and visual surveillance via industrial cameras was established. An intelligent alarm system informs the operator of deviations, while cloud-based analytics support proactive maintenance. Thanks to this integration, the facility could also be expanded with innovative functions such as water consumption analysis.

Technologies Used:

- RevPi Connect as IIoT gateway

- digifai control IoT platform

- Various sensors for level, temperature, and pressure measurement

- Industrial cameras for visual monitoring

Results & Outlook

The power plant operator now has location-independent access to all relevant facility data. The system enables early detection of trends and deviations, making preventive maintenance possible. Downtime can be minimized and facility efficiency increased. In the future, thanks to Revolution Pi's flexibility, the system can be easily expanded with additional functions, such as optimizing energy feed-in or for additional predictive maintenance applications.