Retrofitting in Oil Production

Challenge

Continuous real-time monitoring of wellbores is crucial for economical and efficient oil production. Horizontal or deviated wells, thousands of meters below the earth's surface, present a particular challenge. While standard procedures work well for vertical wells, these modern horizontal wells require significantly more sophisticated mathematical tools. The technical platform needed to execute complex algorithms in C, enable cloud updates, and be industry-grade and temperature-resistant – requirements that a conventional PLC cannot meet.

Canadian company DV8 Energy combines expertise in rod pump physics, advanced mathematics, and IIoT technologies to bring together operators, production engineers, and computer scientists to unlock their collective potential.

Solution

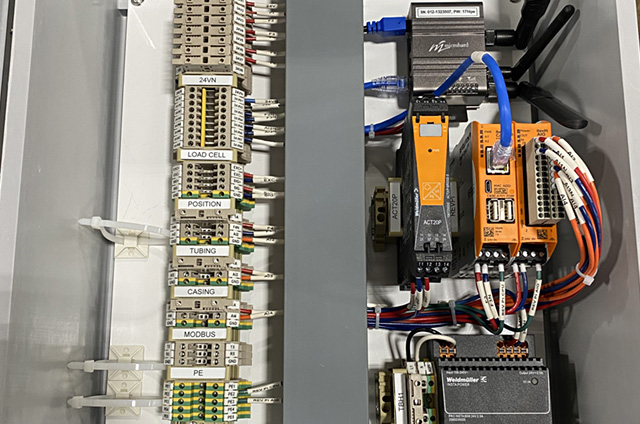

DV8 Energy developed a revolutionary mathematical solution for rod-pumped wells. With the "Edge POC" retrofit box, equipped with the RevPi Core and the analog expansion module RevPi AIO, the system calculates wellbore conditions in real-time.

It analyzes critical parameters such as fluid level, pump intake pressure, dynamic rod stress, pump fillage, gas formation, gearbox torque, and emulsion production directly at the wellhead.

Implementation

The "Edge POC" is integrated into a frequency converter or control cabinet. The RevPi AIO module, with its 24-bit ADC, captures data from load cells, position sensors, and pressure and temperature transducers at 160 Hz. A custom software image enables simple setup and cloud connectivity. Each pump cycle is transmitted to the cloud for analysis. Control is managed through the Props Field Portal software.

Technologies used:

- RevPi Core for algorithm processing

- RevPi AIO with 24-bit ADC

- Modbus TCP communication

- Cloud connectivity for updates

- Props Field Portal software

- Custom software image

Results & Outlook

The RevPi-based system has already saved production and operations teams millions of dollars through performance and efficiency improvements. The solution simplifies the setup and maintenance of remote oilfield locations through automatic programming and diagnostics of drives and measuring devices.