Streamline Your Control Cabinet

With Revolution Pi, you can unify multiple functions into one compact, industrial-grade platform for DIN rail mounting.

- Simplified wiring, fewer errors

- Lower hardware costs

- Streamlined troubleshooting

- Improved, centralized data insights

Learn which use cases you can implement with Revolution Pi!

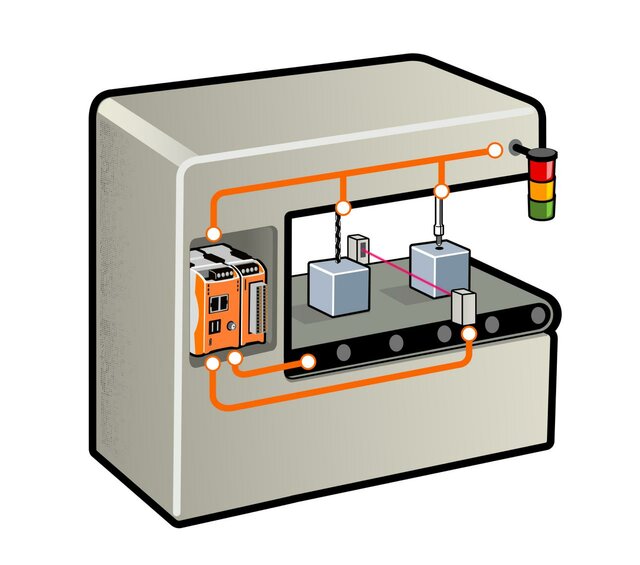

Control Processes

Soft PLC with CODESYS

Combine the reliability of a programmable logic controller according to PLC standard EN 61131-2 with the flexibility of Linux.

With CODESYS, you can program according to the IEC 61131-3 standard in languages such as Structured Text (ST), Ladder Diagram (LD), or Function Block Diagram (FBD). If required, you can add further software.

The real-time Linux operating system enables cycle times of up to five milliseconds. Your process image is created automatically when you configure your expansion modules.

You will find numerous RevPi I/O modules and supported protocols for your application.

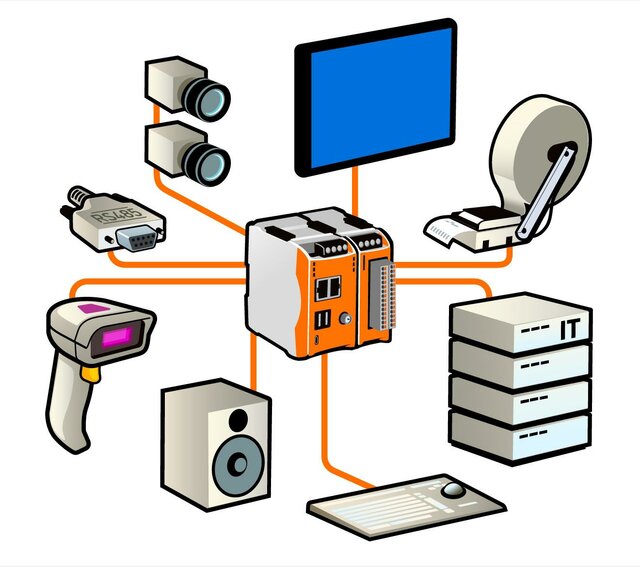

Versatile Connection of Devices

Industrial PC (IPC)

Use Revolution Pi as a compact and robust industrial PC on the DIN rail that combines Linux power with industrial reliability.

The fanless quad-core ARM processor runs reliably at temperatures between -25 and +55 °C and offers powerful computing power for your individual industrial applications.

Connect devices in parallel via USB, HDMI, Ethernet, RS485 and CAN FD and discover the limitless possibilities of manufacturer-independent open source software and extensive protocol support.

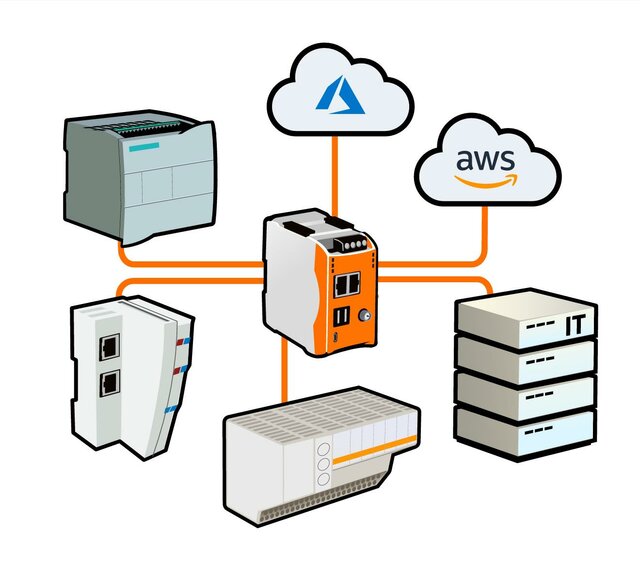

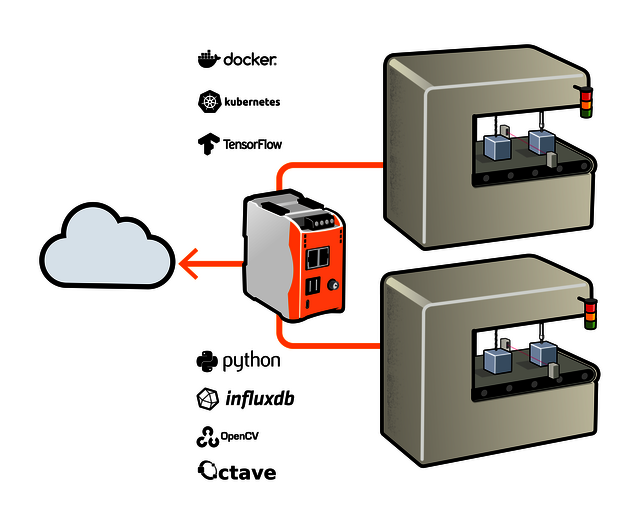

Transfer Data Securely

Industrial IoT Gateway

Revolution Pi lets you connect everything: PLCs from various manufacturers, fieldbus systems and industrial protocols, all common industrial sensor types – from analog to digital to IO-Link.

The powerful protocol conversion to OPC UA, MQTT, and others enables the networking of IT and OT systems such as machines and plants.

Revolution Pi is certified for cloud platforms such as AWS, Azure, and Cumulocity. You can process data locally on the platform and transfer it securely thanks to the integrated Trusted Platform Module (TPM 2.0).

With Balena, you can manage and monitor your device fleet remotely.

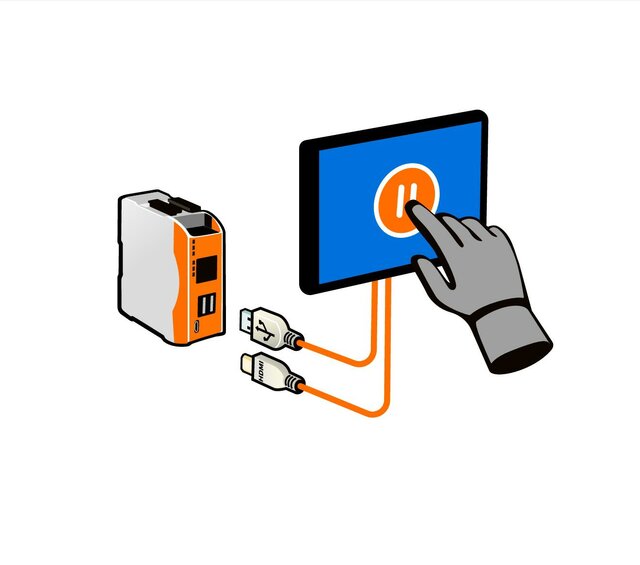

Visualize Data

HMI and Web HMI

Use Revolution Pi as a powerful, flexible visualization system. You can connect industrial-grade touchscreens or production displays via HDMI.

You can develop modern user interfaces with web technologies such as CODESYS WebVisu or Node-RED – even without license costs.

The beauty of web HMIs? They allow access via PC or mobile devices while on the move – always stay up to date instead of running a marathon to the control system. If required, your Revolution Pi can control processes in parallel as a PLC.

Process Data Locally

Edge Device

With Revolution Pi, you don't just access machine and sensor data, you process it directly at the point of origin. Revolution Pi's powerful quad-core ARM architecture is perfect for demanding edge computing tasks.

With minimal energy consumption, you can intelligently analyze and filter data before it goes to the cloud – saving bandwidth and enabling faster responses.

Use Python NumPy and SciPy for calculations and complex models, and Docker containers for microservices.

Revolution Pi processes HD video streams from up to two cameras in real-time and performs sophisticated AI analyses with TensorFlow – ideal for industrial image processing and machine learning directly at the edge.

Revolution Pi Product Series

Find the perfect Revolution Pi for your project: choose between cost-efficient compact devices and high-end systems, models for the control cabinet and the house sub-distribution.

High Quality Standards

Produced in Germany

KUNBUS has been manufacturing all Revolution Pis in Denkendorf near Stuttgart since 2016 using state-of-the-art technology and strict quality controls. Every device undergoes complete end-of-line testing.

Two SMD assembly lines with Fuji machines, robot-assisted production, and a modern wave soldering system guarantee the highest quality.

Made in Germany is not a label for us – it is our promise to deliver industry-standard quality that you can rely on.