Digitalizing in Water Treatment

Challenge

Traditional manual sampling and analysis using vessel methods led to fluctuating water quality and inefficient use of treatment agents. The high manual effort for continuous monitoring also tied up significant personnel resources. Under these conditions, consistent water quality was difficult to guarantee. With increasing demand and stricter quality requirements, Tirta Raharja needed to find a solution that ensures efficiency, reliability, and data integration.

Founded in 1977, Tirta Raharja Water Supply Company is among Indonesia's top 10 water suppliers. As a digitalization pioneer, the company's water treatment plant in Cisarua sets standards for industry modernization.

Solution

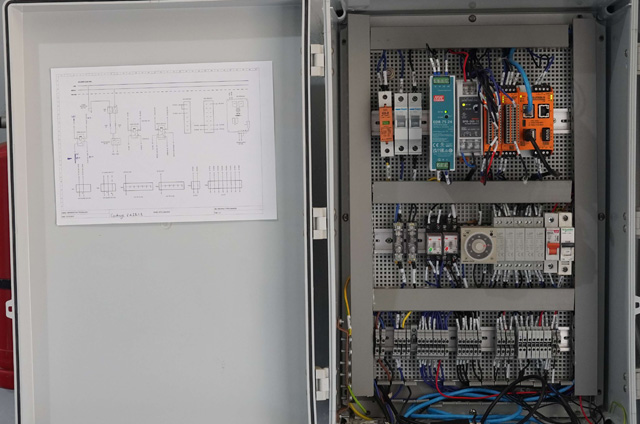

Tirta Raharja opted for comprehensive process automation with Revolution Pi as the central control unit. They chose a RevPi Connect with CODESYS Runtime, enabling fully automated dosing of treatment agents based on real-time data and allowing centralized remote monitoring via SCADA system.

Implementation

The system integrates various sensors and actuators through RevPi expansion modules. A custom SCADA system visualizes the processes and enables remote control. Data is transmitted to a central server via an industrial VPN router and stored in a MariaDB. A redundant system also backs up the data locally.

Technologies used:

- RevPi Connect with CODESYS runtime

- RevPi AIO for sensor connection

- RevPi DIO for dosing pump control

- Industrial VPN router

- MariaDB database

- Modbus communication

Results & Outlook

The automation led to significantly improved process efficiency, consistently high water quality, and substantial reduction in operating costs. Continuous data collection makes the treatment process transparent and traceable. The company has successfully made the leap to Industry 4.0, creating an integrated system that optimally combines IoT, IT, and OT.