Sustainable Retrofitting in Palm Oil Production

Challenge

The palm oil producer faced the typical problems of established industrial facilities: The various production sites operated in isolation from each other, without central monitoring, intelligent controlling, or digital networking. Unlike new facilities, where digitalization and automation can be planned from the start, modernizing the existing plants with their heterogeneous structures developed over years required a special approach.

The goal was to implement a central monitoring and control system that connects the various production sites and consolidates manufacturing data for efficient monitoring of palm oil production. Particularly challenging was the integration of different, historically grown systems into a modern, digital infrastructure.

A Thai palm oil producer is modernizing its facilities with TECHSQUARE, the KUNBUS distribution partner, and their partner K.P.S. Automation and Service, a specialist for the southern palm oil regions of the country.

Solution

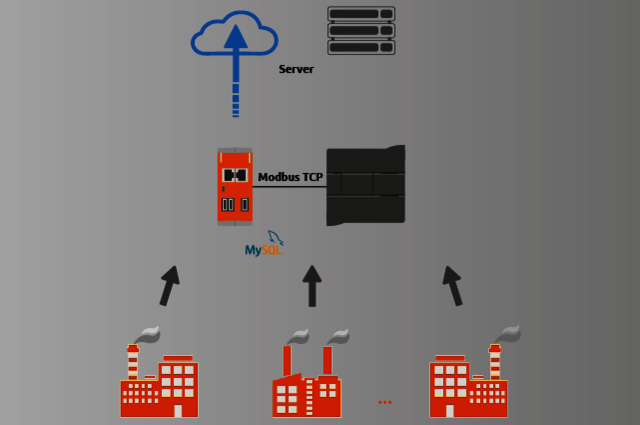

TECHSQUARE and K.P.S. Automation implemented a central data center for monitoring and controlling palm oil production. Revolution Pi serves as the link between existing controls and the new data management system.

Implementation

RevPi Connect communicates with Siemens S7 controllers via Modbus TCP and initially stores data locally for security purposes. An application developed in Python transfers the data to a central server. Special web services enable the processing, storage, and independent calculation of production data. The server consolidates data from multiple production sites.

Technologies used:

- RevPi Connect

- Modbus TCP for S7 communication

- Python-based data transfer

- Web services for data processing and calculation

- Local data buffering

- Integration with Siemens S7

Results & Outlook

The implemented data center enables central collection, monitoring, and control of manufacturing data from various production sites. This first step in the transformation process toward Industry 4.0 creates the foundation for further digitalization measures.