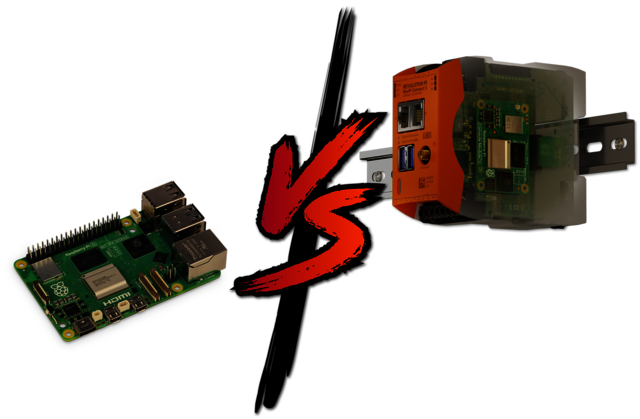

Revolution Pi vs. Raspberry Pi

To ensure that your software runs smoothly around the clock and in the long term, your hardware must meet certain requirements and standards.

This table shows what's important in industrial environments.

| Raspberry Pi | Revolution Pi | |

|---|---|---|

| Construction | Single-Board-Computer | Raspberry Pi Compute Module-powered, modular industrial PC |

| Housing | ❌ Open board | Robust DIN rail housing |

| Operating System (OS) | Raspberry Pi OS | Raspberry Pi OS-based Linux OS with pre-installed applications |

| Power Supply | 5.1 V (USB-C) | 24 V (vibration-proof screw terminals) |

| Industry Standards | ❌ | ✔ PLC standard EN61131-2 ✔ Electromagnetic compatibility (EMC) ✔ UL-certified (for US market) |

| Storage | microSD card | Reliable, built-in eMMC storage |

| Inputs and Outputs | Integrated GPIOs | Industrial I/O modules + process image |

| Integration of Industrial Protocols | Limited possibility | ✔ Comprehensive protocol support |

| Real-Time Capability | ❌ | ✔ Real-time capable operating system |

| Temperature Range | 0 °C to 40 °C | -25 °C to +55 °C (fanless) |

| Protection Against Electrical & Electromagnetic Interference From Other Devices | ❌ | ✔ EMC-tested (IEC 61000-6-2 and -6-4) |

From Prototype to Production

How do these industry standards ensure reliable, continuous operation in professional applications across industries?

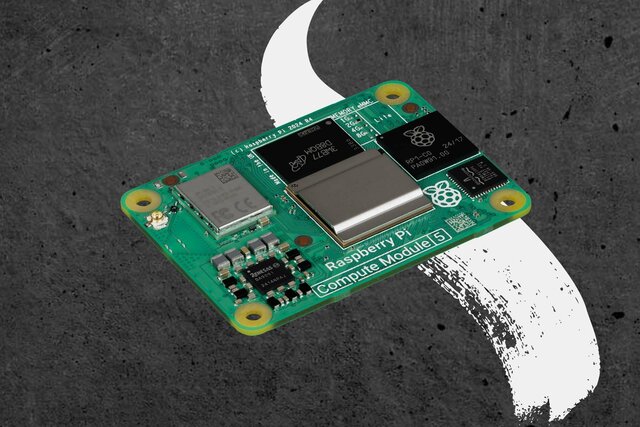

Raspberry Pi Compute Module

The System-on-Module forms the industrial-grade basis for Revolution Pi. It was specially developed and certified for industrial applications.

- Field-tested since 2014

- Currently in the 5th product generation

- Long-term availability until 2036*

*valid for the Compute Module 5 used in the RevPi Connect 5

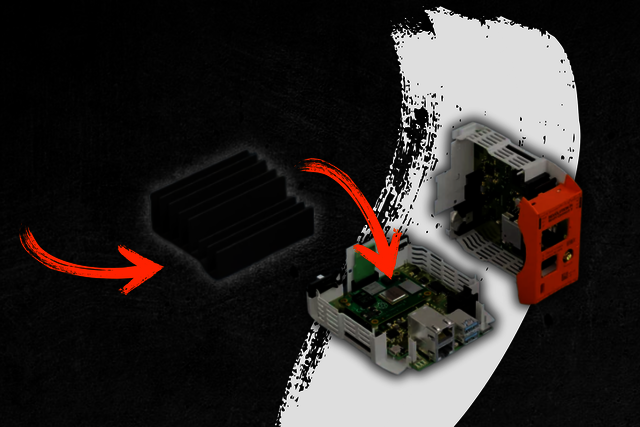

Hardware and Housing

The Raspberry Pi Compute Module is integrated into our customized carrier board:

- Industrial robust interfaces

- Protection circuits against overvoltage and short circuit

This design protects your system. Thanks to its DIN rail housing, you can easily mount the Revolution Pi in the control cabinet.

Industrial-Grade Power Supply

The Revolution Pi works with 24 V via vibration-proof screw terminals, a decisive advantage over connectors that are susceptible to interference.

The wide-range input (10.8 to 28.8 V DC) tolerates voltage fluctuations that can occur in industrial networks.

This way, your application always runs smoothly.

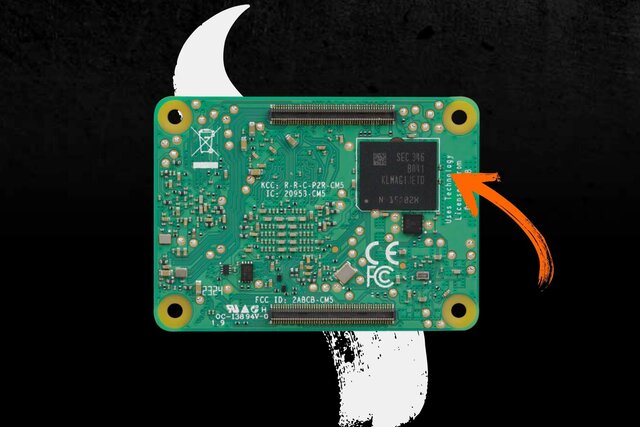

Reliable Storage

Instead of error-prone microSD cards, the Revolution Pi uses the eMMC storage with flash memory, soldered on the Compute Module.

- No connectors to come loose

- No data corruption, even if power fails

- Stable system start, no unplanned system failures

- Optimized flash management to extend memory life

Revolution Pi offers up to 32 GB of reliable eMMC storage for the application and cached data.

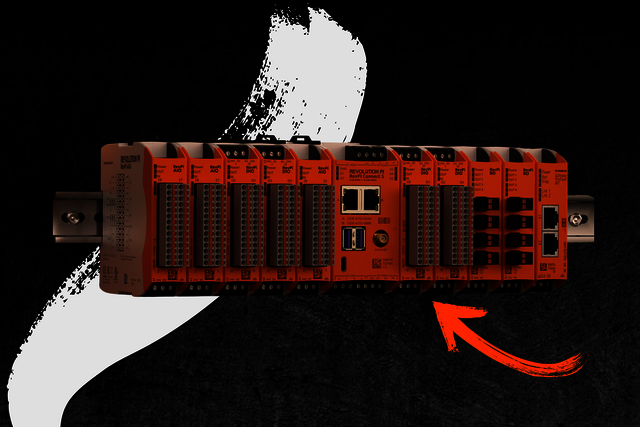

Inputs and Outputs in Industrial Quality

Our RevPi Connect and RevPi Core models can be expanded with up to 10 industrial-grade RevPi I/O Modules:

- Digital, analog and relay modules

- 24 V signal level

- EMC protection against interference from other devices

- Galvanically isolated

Galvanic isolation ensures that your Revolution Pi system is electrically isolated from field devices such as sensors and actuators.

This protects your system from voltage carryover, which can lead to malfunctions or damage.

View I/O Modules

Industry Standards: Control and Communication

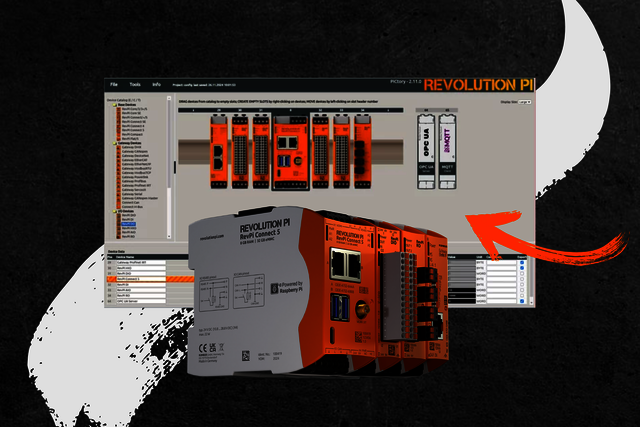

Process Image Instead of GPIO Access

Instead of accessing GPIOs directly as with the Raspberry Pi, the Revolution Pi uses a central process image:

- Bundles all signal states of the inputs, outputs, and fieldbuses in one place

- Similar to industrial controllers

- Configures itself automatically when you set up your RevPi I/O modules in PiCtory.

Your software accesses all I/Os via a standardized interface. This means you can easily run multiple processes in parallel.

Communication via Industry Protocols

With Revolution Pi, you integrate devices easily and save time during system integration.

Revolution Pi supports many industrial protocols:

- MQTT, OPC UA

- Modbus TCP, EtherNet/IP, PROFINET, EtherCAT

- Modbus RTU, PROFIBUS

- Others can be integrated via CODESYS

You can communicate with serial field devices via the RS-485 interface of our RevPi Connect and RevPi Flat models.

Protocol Overview

Real-Time Operating System

A real-time patch in the Linux kernel of our operating system ensures deterministic response times even under load.

This makes Revolution Pi the ideal platform for time-critical, precise process control.

Discover Software Platform

Temperature-Resistant and Fanless

The Revolution Pi runs reliably even at temperatures from -25 °C to +55 °C.

- Fanless design with heat sink

- No moving wearing parts

- No dust intake

- Housing with chimney effect for enhanced cooling (ventilation openings at the top and bottom)

This ensures the longevity of your Revolution Pi in demanding environments. The average operating time (MTBF value) is 30.7 years at 25°C.*

*Applies to the RevPi Connect 4

Discover the Revolution Pi Series

Find the perfect Revolution Pi for your project: choose between cost-efficient compact devices and high-end systems, models for the control cabinet and the house sub-distribution.