Kaizen Meets Revolution

Challenge

Automotive production is often characterized by paper-based work instructions. These carry the risk of misunderstandings and incorrect execution, especially in complex manufacturing processes. The goal was to transform these documents into digitalized, interactive instructions that are easier to understand, adaptable, and traceable. At the same time, the system needed to be flexible enough to integrate with existing infrastructure and automation technologies.

TECHSQUARE, KUNBUS distribution partner in Thailand, worked with a Japanese automotive corporation to develop a solution for digitalizing work instructions in their Thai plants. The project follows the Japanese Kaizen concept of continuous improvement.

Solution

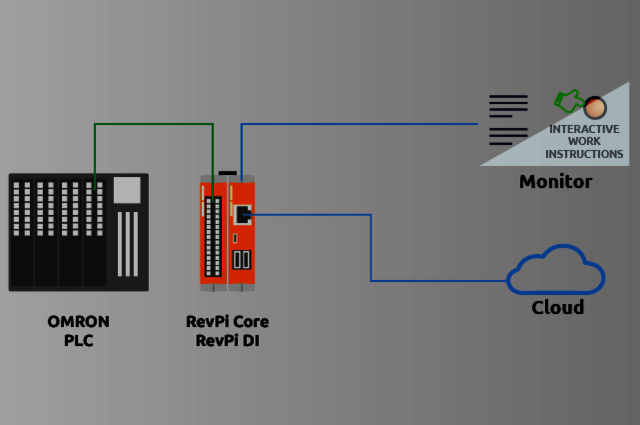

TECHSQUARE implemented a Revolution Pi-based solution that seamlessly integrates with existing OMRON PLC controls. The digitalization enables the display of work instructions on monitors at workstations and central logging of all work steps in the cloud. This integration enables real-time presentation of instructions and process information.

Implementation

A Revolution Pi system, consisting of RevPi Core and the digital I/O expansion module RevPi DIO, was connected to the OMRON PLC. The system receives process data via the I/O module and displays corresponding work instructions on a monitor through the HDMI interface. Work steps are logged via Ethernet connection to a cloud for later tracking and analysis.

Technologies used:

- RevPi Core as central control unit

- Digital I/O expansion module RevPi DIO

- HDMI display for work instructions

- Ethernet connection to cloud

- Integration with OMRON PLC

Results & Outlook

The project underlines how small improvements following the Kaizen principle can lead to major efficiency gains. Through digital transformation, the execution quality of work instructions was significantly improved. Simultaneously, the system enables central documentation and analysis of all process steps, contributing to long-term improvement of production processes.