Smart Riveting

Challenge

Integrating mobile hand tools into networked production systems places special demands on data collection and transmission. For effective quality assurance and process monitoring, all work steps must be reliably documented. This includes detecting failed attempts and distinguishing them from successful riveting operations. The challenge was to develop a modular, easily integrated system that meets all these requirements.

As part of the HONSEL Group, VVG-Befestigungstechnik develops riveting tools of all classes, from manual hand riveting pliers through pneumatic tools to modern battery-powered riveters of the Rivdom/RivSmart family and fully automatic industrial systems.

Solution

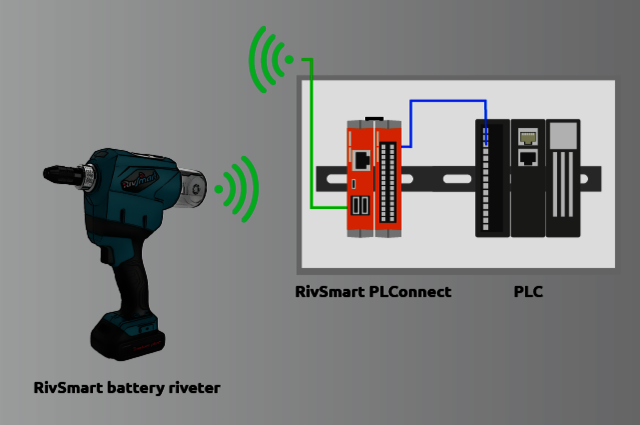

For RivSmart PLConnect, HONSEL uses the RevPi Core, a flexible, industrial control unit that supports various standards such as Modbus and WLAN. Besides collecting and transmitting process data, the system enables seamless integration into existing PLC infrastructures. Additional modules can be integrated via digital and analog interfaces, making the system highly customizable.

Implementation

RivSmart PLConnect acts as an intelligent interface between battery-powered riveting tools and the plant PLC. All relevant process and documentation data is transmitted from the riveting tool via WLAN. Riveting data, service messages, and failed attempts are securely transmitted via WLAN. The system also allows precise process monitoring and offers functions such as filtering of empty strokes. The RevPi Core's modular architecture ensures easy extensions and compatibility with DIN standards.

Technologies used:

- RevPi Core as central control unit

- Digital and analog I/O expansion modules

- Industrial gateways for network integration

- WLAN communication

- HONSEL-specific control software

Results & Outlook

The system enables complete documentation and quality assurance of riveting processes while integrating into networked production. The modular architecture allows customer-specific adaptations and future expansions. This is an important step toward fully networked, intelligent manufacturing where hand tools are also integrated into the digital ecosystem.