Efficient Water Treatment with IIoT

Challenge

In industry, reliable process water is essential. It becomes even more valuable when you can intelligently monitor and control treatment plants – no matter where in the world they're located. We'll show you how Ekopak and Factry achieved exactly this with Revolution Pi.

Ekopak's mobile water treatment plants process river water into high-quality process water worldwide. This continuously generates important process data that is essential for monitoring and optimization. The central question was: How can this data be reliably collected and made usable in real-time – even when the plants are located in remote areas?

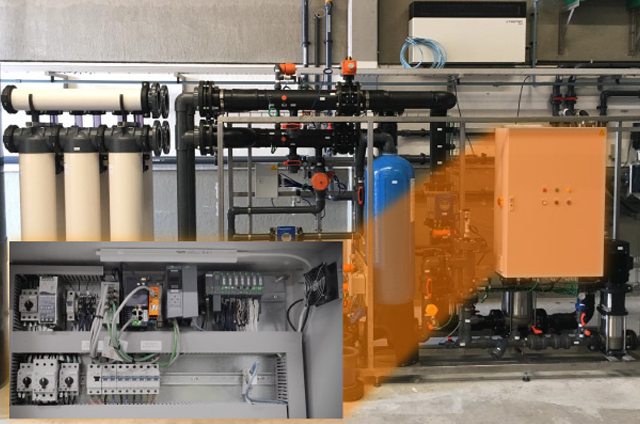

Belgian specialist Ekopak builds complete water treatment plants into standard containers. These mobile systems deliver customized process water for industries ranging from breweries to textiles.

Solution

Ekopak developed together with software company Factry a clever IoT solution: A pre-installed RevPi Core acts as data collector and cloud gateway. It captures data from the Siemens S7-1200/1500 PLC via OPC UA and transmits it to the cloud via 4G. There, the data is visualized in meaningful dashboards.

Implementation

The installation is as simple as it is ingenious: Factry pre-configures the RevPi Core with its OPC UA collector and sends it to Ekopak. On-site, it only needs to be connected and started. The rest runs automatically: The RevPi independently connects to the cloud infrastructure and begins collecting data. Up to 500 measurements per second are captured and transmitted.

Technologies used:

- RevPi Core as IIoT gateway

- OPC UA for PLC communication

- 4G mobile for cloud connectivity

- Grafana for visualization and monitoring

- Open-source software stack

Results & Outlook

With the new solution, Ekopak gains completely new insights into its processes. Through real-time monitoring, the company identifies problems immediately and resolves them promptly. The open architecture makes it easy to add new sensors and analysis functions, allowing Ekopak to continuously optimize processes. The Revolution Pi platform reliably collects data, alerts in real-time, provides detailed analysis, and remains future-proof through its open-source technology.