Automated Storage and Retrieval System

Challenge

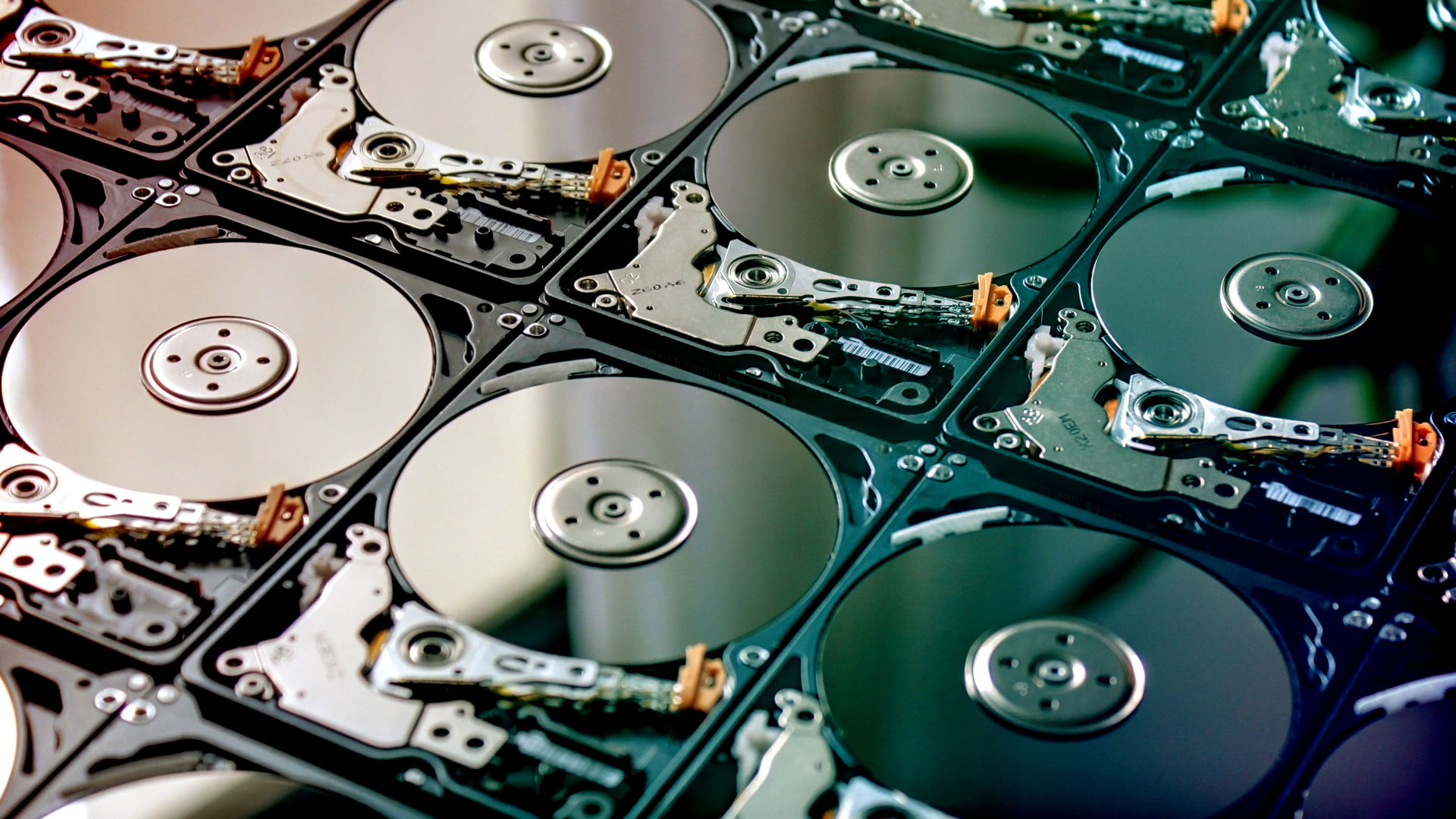

A major hard drive manufacturer in Southeast Asia needed an automated solution to quickly and securely store and retrieve hard drives. The system needed to operate without an Internet connection while efficiently preparing up to 100,000 drives per batch for shipment. High precision and safety were essential to avoid downtime and damage.

British company Lumico Digital collaborates with automation expert Dave Bowyer to develop customized IoT solutions for optimizing automation processes.

Solution

After comprehensive analysis, Revolution Pi was chosen as the central control unit to coordinate both robots as well as all sensors, grippers, and conveyor belts. Revolution Pi offers a modular, flexible platform that is designed for industrial requirements and can be adapted to specific automation needs.

Implementation

The system features two robots working in tandem:

- Robot 1: Operates on the X and Z axes to grip and prepare drives for transport.

- Robot 2: Takes the drives and places them on a conveyor belt or shelves for later retrieval.

All components, including servomotors and gripper arms, are controlled via Revolution Pi. Integrated I/O modules manage sensors and actuators, ensuring real-time monitoring. The system quickly stops during unexpected events to prevent damage. Modbus TCP manages servomotor commands via Ethernet. A built-in VPN router enables secure remote maintenance. The system operates offline, ensuring autonomy without internet access.

Technologies used:

- RevPi Connect: central hardware platform

- RevPi DIO, DI, DO: I/O expansion modules for sensor and actuator integration

- Modbus TCP: communication protocol for motor control

- Ethernet: network connection between modules and controller

- Web-based interface: real-time monitoring and control

Results & Outlook

Through the implementation of the customized robotic system, the hard drive manufacturer significantly increased the efficiency and speed of their warehouse processes. The automation enables the preparation of large batches of up to 100,000 hard drives for shipment, reducing costs and improving reliability.

Lumico Digital demonstrated their expertise in IoT-based automation through this successful implementation, creating a solution that combines efficiency and security in demanding logistics processes.