Digital Twin

Challenge

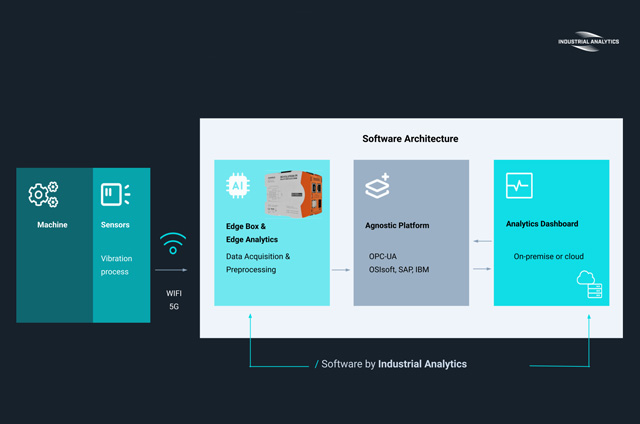

Creating a precise digital twin of an industrial facility requires high-quality data from various sources. This data must not only be reliably collected but also pre-processed directly at the source (edge). Particularly challenging is combining process data from the control system with high-frequency machine data from acceleration sensors into a meaningful overall picture.

Industrial Analytics IA GmbH combines engineering knowledge with AI to optimize rotating machines and industrial facilities. Part of Infineon Technologies since 2022, customers like Vattenfall and PCK Raffinerie benefit from innovative vibration analysis and sustainable IoT solutions.

Solution

Industrial Analytics developed an edge box using Revolution Pi as the central component. The RevPi Connect was chosen for its Linux compatibility, enabling the use of the high-performance programming language Julia. Combined with the RevPi AIO module, various process data such as temperature, pressure, and current can be collected and pre-processed.

Additionally, hybrid AI models that combine physical knowledge with machine learning enable precise data analysis and effective plant optimization.

Implementation

The edge box functions as an intelligent pre-processing system. It collects both process data from the customer's control system and machine data from a special measurement card for acceleration sensors. Revolution Pi serves as an edge computing platform that collects, pre-processes, and prepares data for cloud analysis. The data is evaluated using edge analytics software, divided into batches, and prepared for further analysis in the cloud. Thanks to its API-based architecture, the system easily integrates into existing infrastructures without additional tools or complex configurations.

Technologies used:

- RevPi Connect as edge computing device

- RevPi AIO for process data collection

- Julia programming language for real-time data processing

- Edge analytics software

- Acceleration sensors with special measurement card

- Integrated watchdog for system security

"The RevPi Connect and the RevPi AIO modules perfectly meet our requirements for high-quality data collection and pre-processing on the edge box."

Rubens Rossi, Vibration Analysis Expert at Industrial Analytics

Results & Outlook

The system enables the creation of precise digital twins that can be used to identify anomalies and simulate new operating conditions. This creates decisive competitive advantages through optimized plant efficiency and predictive maintenance. In the future, product innovations and alternative fuels can also be simulated in the digital twin.