Smart Rail

Challenge

The rail industry is undergoing a digital transformation with significant growth opportunities. Modern standards such as Automated Train Operation (ATO) and the European Train Control System (ETCS), along with advanced signaling technology, aim to set new benchmarks for efficiency and safety. Lucy, a Thales Germany test vehicle originally equipped with relay-based controls, needed a major upgrade to meet these requirements. The challenge was to integrate advanced sensors, provide immense computing power, and ensure that the new control system could achieve SIL4 certification according to EN50128.

Railergy specializes in innovative railway solutions, providing services and products to improve the efficiency, safety and sustainability of railway applications. The company focuses on autonomous train operation, retrofitting existing systems, and integrating advanced control technologies such as European Train Control System (ETCS) and Driver Advisory Systems (DAS).

Solution

Railergy developed a Train Control and Measurement System (TCMS) based on Revolution Pi. This open, Linux-based platform provides the flexibility, performance and storage capacity to support model-based development tools. It can accommodate virtually any software or application. The software developed is SIL4-certifiable and can be easily ported to other platforms.

Implementation

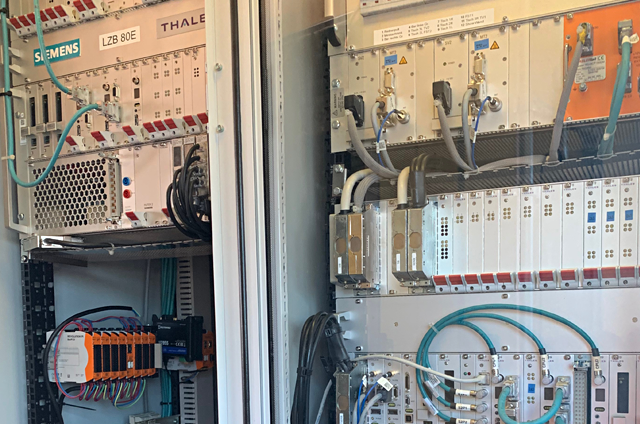

The system uses several Revolution Pi modules: a RevPi Connect and a RevPi Core with digital and analog I/O expansion modules (RevPi DI and RevPi AIO). These integrate with the existing relays, digital status outputs, and analog sensors. A 5G communication module enables remote operation, allowing the vehicle to be controlled autonomously. The driver operates Lucy from an external control station equipped with a dedicated remote control system, also built with a RevPi setup.

Technologies used:

- RevPi Connect for centralized control

- RevPi Core

- RevPi AIO and RevPi DIO

- 5G mobile communication

- Dedicated remote control system

- Model based development tools

- SIL4 certified software

- Integration with existing relays and sensors

Results & Outlook

Lucy now serves as an open test platform for current and future rail technologies. The system transforms the old vehicle into a state-of-the-art test lab, enabling autonomous operation, advanced train protection and flexible remote control – key requirements for the digitalization of the railway industry.