Saving Energy Intelligently

Challenge

A solution had to be developed for major customers in the gas transport network to provide real-time consumption data and enable process optimisation. The main challenge was to create a digital twin of the industrial plant that met the highest cyber security standards: production networks had to be completely isolated from external access in case of an emergency, while ensuring real-time data updates.

Teréga Solutions, a subsidiary of the Teréga Group founded in 2021, is a key player in the French gas infrastructure. The company develops practical solutions for energy efficiency and CO₂ reduction, ranging from hydrogen and biomethane to digitization projects.

Solution

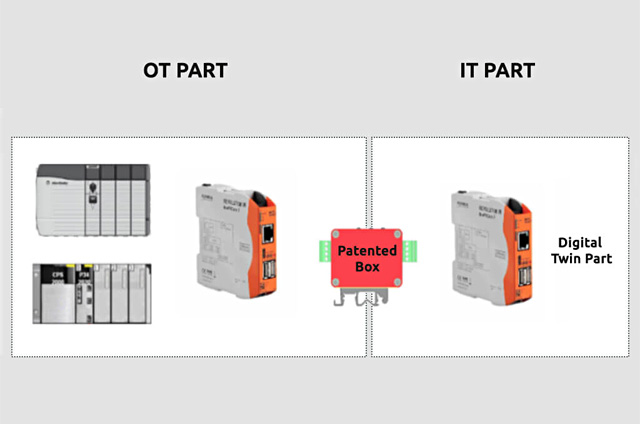

Teréga Solutions developed the Indabox, a combination of a patented diode-based module for unidirectional data transmission and two Revolution Pi modules.

The choice of Revolution Pi was based on several factors: its embedded Linux system, 24V DC power supply, industrial reliability, compact design and freely programmable status LEDs for diagnostic purposes.

Implementation

The Indabox uses an innovative architecture designed for maximum security: one RevPi Core reads data from the PLC and transmits it through the diode-based security module (the red device in the figure) to a second RevPi Core connected to the Internet. This second module communicates the data over a 4G connection using API or MQTT protocols to the IO-BASE platform that hosts the digital twin. The system transmits 1,500 data records every 5 seconds and also supports local data access via a Modbus RTU serial interface.

Technologies used:

- 2 x RevPi Core

- Patented diode-based safety module

- 4G communication module

- IO-BASE platform solution

- API and MQTT interfaces

- Modbus RTU

Results & Outlook

The Indabox is already installed in more than 50% of the distribution stations and will soon be available to all industrial customers and large consumers in the Teréga network. The solution enables companies to correlate their consumption indicators with operating parameters and adjust processes in real time. Its seamless integration with existing systems provides a particularly cost-effective approach to energy optimization.

Revolution Pi for Your Energy Solution?

Numerous companies rely on Revolution Pi as industrial-grade, flexible hardware for their energy solutions.

The open Linux platform offers you complete freedom in application development.