Intelligent Residual Current Monitoring

Challenge

For predictive maintenance of electrical systems, a solution had to be developed that continuously monitors and documents residual currents. The system needed to be modular and flexibly adaptable to various applications – from single solutions to complex industrial facilities.

Additionally, common problems like complex wiring and slow data transmission, which frequently occur in control cabinets, needed to be overcome. Traditional protocols like Modbus are insufficient here, especially for rapid current spikes or load drops.

Doepke Schaltgeräte GmbH develops and produces solutions for safe and intelligent power usage. The company focuses on circuit breakers and control devices, along with related consulting, technical support, and training.

Solution

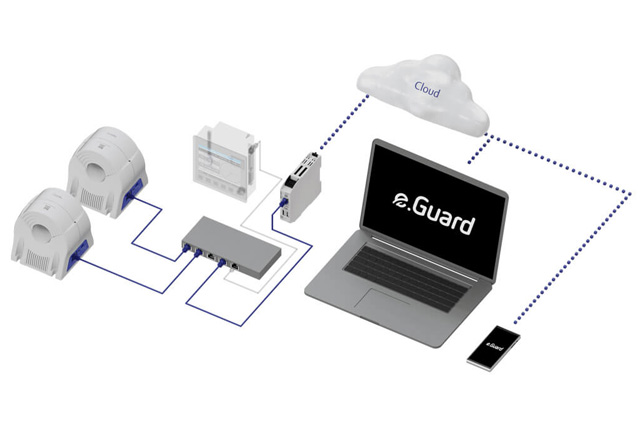

Doepke developed e.Guard, a smart system for condition monitoring of electrical systems. The system combines sophisticated hardware with flexible software. All-current-sensitive residual current monitors detect and evaluate residual currents in eight frequency ranges up to 30 A. From Level Two upward, the RevPi Core is used as an e.Guard gateway, which from Level Three additionally serves as an interface to the e.Guard cloud. The Revolution Pi devices are specially customized for Doepke as OEM products, including design modifications and customer-specific software images.

Implementation

The modular system is built in five levels. The local or cloud-based software visualizes, stores, and documents the detected residual currents. Thanks to Revolution Pi as gateway, data can be reliably collected in short cycles and transferred to the cloud, overcoming the limitations of conventional systems. Through continuous monitoring, recurring insulation tests according to DIN VDE 0105-100/A1 can be eliminated, significantly reducing maintenance effort. Moreover, Revolution Pi's open architecture enables integration without vendor lock-in, offering customers maximum flexibility.

Technologies used:

- RevPi Core as e.Guard gateway

- All-current-sensitive residual current monitors

- Cloud connectivity

- Machine learning for fault detection

- Local and cloud-based visualization software

Results & Outlook

The system enables true predictive maintenance in electrical systems. The collected residual current data can be used through machine learning to detect creeping faults early. With the innovative architecture, not only is safety increased, but installation and maintenance effort is significantly reduced. The modular design allows flexible adaptation to future requirements.