Retrofit Palm Oil Production

Until now, individual production plants or factories operated separately without monitoring mechanisms, intelligent controlling and digital networking. While it is now relatively easy to digitalize and automate processes and production steps from the start in new plants, it is more challenging for existing, older plants.

One of the famous palm oil producers in Thailand found itself in exactly this situation and was looking for a solution that would help to modernize its production facilities with their heterogeneous structures that had grown over the years. Through our local distributor, TECHSQUARE, and its network partner in the southern part of Thailand, K.P.S. Automation and Service, providing the first design with Revolution Pi for the palm oil producing industry, the company has taken the first step in the transformation process to Industry 4.0. A data center was implemented with the aim of centralizing all production data and thus ensuring simple monitoring and control of palm oil production.

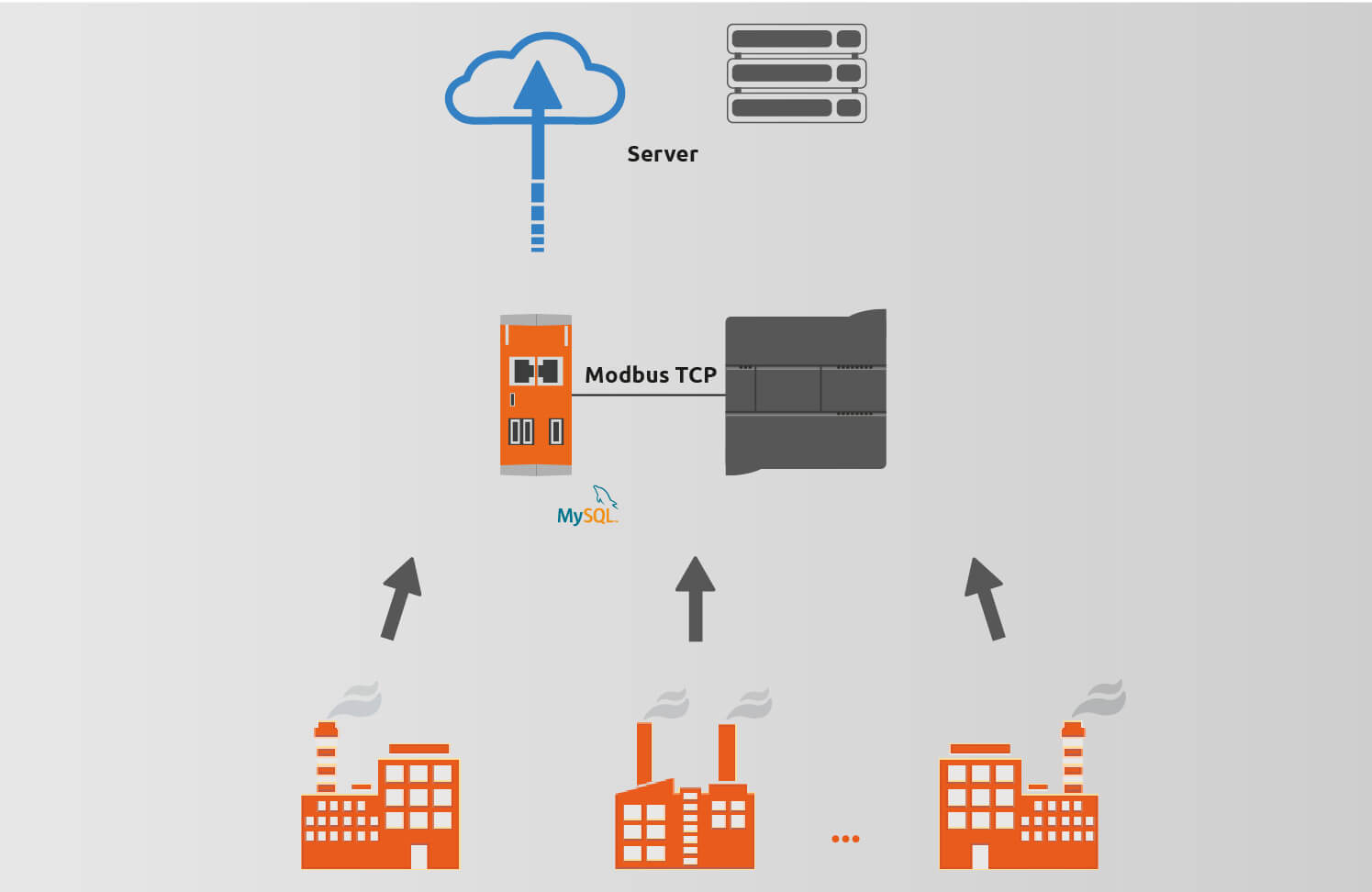

The RevPi Connect and the Siemens S7 communicate via Modbus TCP. The data on the RevPi Connect are buffered locally for security reasons before they are exchanged with a server. A small application was programmed in Python for the data transfer. Using special web services, it is possible to process and store the production data centrally on the server, as well as to perform own calculations. The server thereby combines the data of several palm oil production sites, so that several RevPi Connect modules are used at several production sites.

About TECHSQUARE

TECHSQUARE has already developed many successful digital transformation projects in Thailand using the Revolution Pi platform.

About KPS Automation and Service

K.P.S. Automation and Service provides engineering services in the southern palm oil producing community of Thailand.

For more information, visit https://www.techsquare.co.th.

Module used

RevPi Connect